-

Products

- Lab Instruments

-

Lab Meters and Probes

Calibration Standards Other Meters and ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analyzers

Streaming Current TOC Turbidity Analysers EZ Series Analysers

- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

-

Online Sensors and Controllers

pH & ORP Sensors

- 12mm pH/ORP

- 8362 sc High Purity

- Clean & Cal pH Mount

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

- Automated Lab Systems

- Samplers

- Multiparameter Online Panels

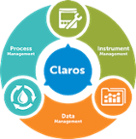

- Claros Water Intelligence System

- Test Kits & Strips

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments- Balances

- Floc Testers/Jar Testers

- Hot Plates & Stirrers

- Microscopes

- Moisture Analysers

- Other Instruments

- Ovens & Incubators

- Thermometers

- Timers

- Vacuum Pump

- Water Purification Systems

-

Microbiology

Accessories and Chemicals Dehydrated MediaInstruments KitsLabware

- Accessories

- Funnels, Pumps & Manifolds

- Microbiology Filters

- Petri Dishes & Accessories

- Sampling Bags

- Vials, Tubes, Bottles & Racks

- Industrial UV

- Parameters

- Applications

- Industries

- Service & Support

- Brands

Hach helps brewery reduce costs and ensure beer quality in Hanoi, Vietnam

In the brewery, carbon dioxide generation by yeast during fermentation, together with heat and alcohol due to requirement of CO₂ at the end of the manufacturing process. This is to add the fizzy effect to the final beer and when recovering the CO₂ during fermentation would help reduce cost.

- Monitoring of CO₂ purity in the brewery

- CO₂ recovery during fermentation stage

The challenges faced for this customer, is that great care needs to be taken to avoid contamination of the final beer by air as oxygen would reduce the product shelf-life and contributes to off tastes known as stall or cardboard.

Because Hach is very experienced in monitoring process in the brewery, client has handed their challenge to us. Hach helped client install CO₂ recovery system that includes sensor and controllers at the point sampling to recover the CO₂ during fermentation stage.

Hach is proud to be the choice for clients’ water quality testing solution provider.

Want to know how Hach helped control and reduce costs and ensure beer quality for the whole brewery process, while maintaining its taste, flavor and shelf-life?

See how Hach managed to do so, by downloading the full version of this case study now!