-

Products

- Lab Instruments

-

Lab Meters and Probes

Calibration Standards Other Meters and ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analyzers

Streaming Current TOC Turbidity Analysers EZ Series Analysers

- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

-

Online Sensors and Controllers

pH & ORP Sensors

- 12mm pH/ORP

- 8362 sc High Purity

- Clean & Cal pH Mount

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

- Automated Lab Systems

- Samplers

- Multiparameter Online Panels

- Claros Water Intelligence System

- Test Kits & Strips

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments- Balances

- Floc Testers/Jar Testers

- Hot Plates & Stirrers

- Microscopes

- Moisture Analysers

- Other Instruments

- Ovens & Incubators

- Thermometers

- Timers

- Vacuum Pump

- Water Purification Systems

-

Microbiology

Accessories and Chemicals Dehydrated MediaInstruments KitsLabware

- Accessories

- Funnels, Pumps & Manifolds

- Microbiology Filters

- Petri Dishes & Accessories

- Sampling Bags

- Vials, Tubes, Bottles & Racks

- Industrial UV

- Parameters

- Applications

- Industries

- Service & Support

- Brands

Southeast Asia

Choose your country or region:

Europe

Americas

Asia - Australasia

- Australia

- Mainland China

- India

- Indonesia

- Japan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Thailand (Thai)

- Taiwan

Middle East - Africa

Chemistries 65-6265-9381

Food Industry

Complete Water Analysis for Food Industry Applications

Abundant, clean water is essential to food processing. It is not only a key ingredient but it’s also a medium to clean and move raw materials and is the principal agent used in sanitizing plant machinery.

At Hach ®, we understand your water needs when it comes to ensuring the highest levels of water handling efficiency, product quality, consistency, safety and social responsibility.

Monitoring Influent to Meet Regulations,

Reduce Costs, Protect the Environment

Water is a critical topic in the food industry, as companies are encouraged to pay more attention to wastewater management to meet stricter regulations, protect social reputations and reduce energy consumption.

Global food companies have established internal wastewater guidelines requiring their operations to monitor key influent and wastewater parameters and comply with limits by sampling at set frequencies. These leading food processors are using science-based rules aimed at having a net-zero impact on their local communities’ water resources.

Hach Solutions for the Food Industry

Whether it is to maintain product quality, prevent product loss, meet your compliance limits or optimize your water treatment, we have customizable solutions for your unique challenges.

Hach can help you:

- Reduce water consumption

- Maximize water reuse

- Increase energy efficiency

- Reduced CO 2 footprint

- Mitigate water waste and environmental impact (from Net-H 2O-Zero to Net-H 2O-Positive)

- Increase your Return on Investment (ROI) whilst protecting your operation and your customers with our ultralow-range analytical tools

Key Measurement Parameters in Food Plants

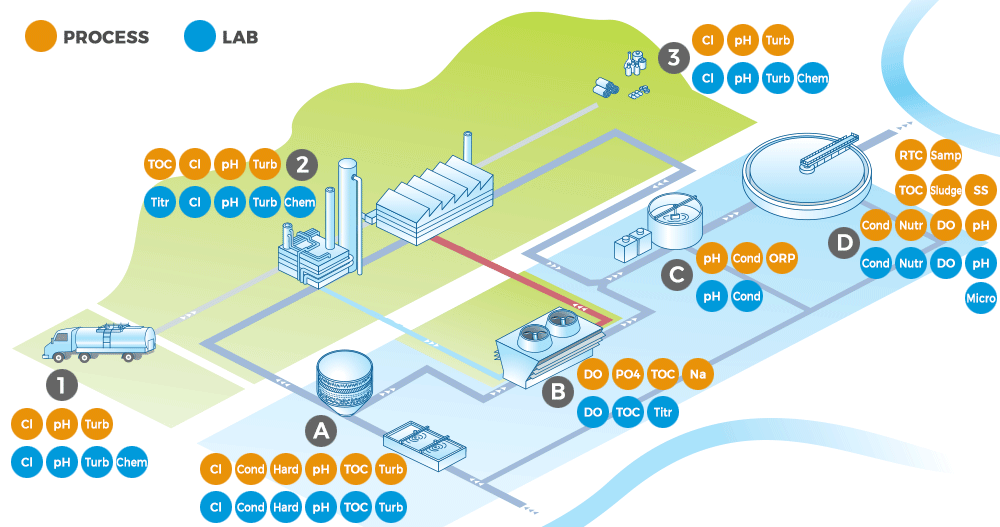

1 - Delivery of Stocks

2 - Production

3 - Dispatch

A - Water Conditioning and Treatment

B - Steam/Power Generation and Cooling

C - Neutralization

D - Biological Wastewater Treatment

Hach and Water Efficiency & Security

Hach supports our customers’ pledges, which are aligned with the principle of attaining a circular water economy within their manufacturing operations. The “ Net Zero Water” objective for the industry aims at reducing absolute water use by 100%, and the more ambitious “Net Water positive” goal seeks to replenish back into the local watersheds more than 100% of the water used.

We focus on providing the tools that improve operational and agricultural process water-use efficiencies, as well as local water replenishment in high water-risk areas suffering from a lack of water security. We work to understand the water challenges at your local level and support solutions that address the specific needs, not only of your operation but also of the watershed where it operates.

Hach supports the establishment of science-based targets (SBT), as directed by the 2025 water-sustainability commitments from our customers in the food industry.

Featured Food Applications

- Beverage

- Food and vegetable oils

- Fruits, vegetables, corn, grains, fish/seafood, flavorings, additives, etc.

- Meats and poultry

- Milk and dairy

- Sweeteners, sugars

- Vegetable proteins

Beverage

From beer to soft drinks to bottled water and wine, Hach can help you meet the beverage quality control demands at your facility. For full information on Hach solutions for the beverage market, see our Beverage Industry page.

Food and Vegetable Oils

Ensuring the quality and sanitation of vegetable oil production for human consumption, from soybean, olive, sunflower and other edible oils is of paramount importance to food processors. Hach supplies the analytical solutions that your extraction and oil processing plants require by providing timely information to your wastewater management teams to assess compliance and industry regulation requirements, in addition to optimizing the reuse of as much of this vital element as is technically and economically feasible.

Fruits, Vegetables, Corn, Grains, Fish/Seafood, Flavorings, Additives, etc.

Food processors require large quantities of high-quality water for a range of operations, including blending or mixing, cleaning, steam production, etc. All of these factors are important for overall quality assurance and sanitation. As water may contain dissolved minerals, organic matter, gases, and microbial contaminants, understanding water quality and how it moves through the factory is one part of the equation needed to produce safe, high-quality foods.

Meats and Poultry

The use of water with adequate, chemical and microbiological quality is of fundamental importance. Food processors must take steps to ensure that the water and water systems in their plants are safe and under their control.

Milk and Dairy

Dairy processing is a challenging environment for analysis of FOGS (Fats, Oils, Grease and Solid Waste), salts and particulates that are inevitably present in process streams. Saving time or increasing the reliability of your analyses to stay in compliance with industry regulations is key.

In the dairy market, efficient monitoring of the production process allows the customer to increase productivity and reduce costs by eliminating unnecessary acquisitions and purchase of raw materials.

Our BioTector instruments help with monitoring product loss to assist in theidentification of faulty equipment or water reuse streams in your application. Read this Case Study where Hach has seen that as a result of using reliable TOC monitoring, a client achieved a considerable milk waste reduction, thus reducing processing costs at their Waste Water Treatment Plan (WWTP). Typically, lost product levels can be reduced by a 15% (conservative as some clients have seen up to 40% reduction).

Sweeteners / Sugars

By providing information to manage the water in our customers’ wet corn or sugar mills, we have learned how critical it is to measure the factors which influence overall quality assurance and sanitation in these operations.

Our understanding of water quality standards in the sweeteners industry and how they are impacted within the different processes at the factory positions us to become a partner of choice to assist our customers in producing safe, high-quality food ingredients.

Vegetable Proteins

In the food processing industry, increased vegetable oil and protein consumption is gaining market acceptance. The related processing facilities require significant amounts of water - not only for growing the vegetables but for processing these in operations such as cleaning, blending, mixing, steam production, etc.

We holistically support the analytical requirements for your plants, from providing information to manage the quality of your influents to detecting product loss in your wastewater streams.

Select an Application

Influent/Raw Water

Incoming water quality directly impacts product quality. The consistency and purity of your influent or raw water greatly affects the taste and quality of your final product. We understand that the demands of monitoring and treating influent or raw water impact the longevity of your equipment and product quality.

Proper treatment and conditioning are essential for water as it enters any production process. The water used in production lines of food facilities must not only meet drinking water regulations, it must be treated to remove additional minerals and chemicals which could impact taste and production processes.

Parameters Relevant to Influent/Raw Water Processes:

- Chlorine

- Conductivity/ Total Dissolved Solids (TDS)

- pH/ORP

- Turbidity

- Dissolved Oxygen Carbon (DOC)

- Total Organic Carbon (TOC)

- Coagulation Control

- Hardness

Boiler & Cooling

We understand the challenges in monitoring the water in boiler and cooling processes. Condensate is critical to processes requiring high temperatures. When steam flows out from the boiler it passes through a series of heat exchangers that heat the process liquid.

TOC measurement in the condensate provides early warning to organic contamination of the steam. This stage in the process can also be a point where organic contamination is introduced into the condensate return system.

Optimizing boiler feed water and cooling tower feed minimizes chemical usage, prevents corrosion and protects plant equipment.

Parameters Relevant to Monitor Boiler/Cooling Processes:

- Dissolved Oxygen (DO)

- Conductivity/ Total Dissolved Solids

- Free & Total Chlorine

- pH

- Total Organic Carbon (TOC)

- Total Hardness

- Ammonia

QA/QC Lab

QA/QC is responsible for the overall quality of the products that meet standards. Quality control procedures are vital to provide sustainable high-quality products. It is key to have accurate measurements, reliable results and easy-to-use tools. Avoiding breakdowns and human error is crucial to optimizing quality control.

In-line process quality control provides production staff with analysis results 24 hours a day. Taking the guesswork out of the process improves efficiencies and reduces cost.

Understanding the different methods available also empowers you to make the right decisions regarding your plant and final product.

Parameters Relevant in QA/QC Applications:

Clean-in-Place (CIP)

Clean-in-Place is commonly used in hygiene critical industries to clean a wide range of areas in the plant. CIP refers to the use of a mix of chemicals, heat and water to clean machinery, vessels or pipe work without dismantling plant items.

CIP ensures the cleanliness of food production surfaces. Food manufacturers design and qualify CIP procedures to ensure no microbial growth will contaminate products.

Parameters Relevant in CIP Applications:

Water Reuse

Reducing environmental impact is a key reason to optimize water reuse within your plant. Water reuse, including reclaimed and recycled water, is one method food facilities can employ to enhance sustainability practices and safeguard water quality standards by reducing the plant’s dependency on external water sources.

With water scarcity a serious concern worldwide, there is a need for industry to address the impact of its water consumption and consider ways in which it can optimize water use in the future while ensuring quality products. Examples include reverse osmosis systems.

Recovering and reusing wastewater from a manufacturing process requires treatment, whether basic or rigorous. Monitoring for parameters and compounds such as TOC, BOD, COD and TSS provides treatment operators with the information they need to assess quality and improve the efficiency of treatment processes.

Parameters Relevant to Water Reuse Processes:

Product Loss

Prevent profit from being depleted. Increase product yields and reduce overall costs by maximizing the monitoring of organics in your process. Losing otherwise salable product adds significant cost beyond the product loss itself in the form of higher energy, water and treatment costs.

Using real-time organics monitoring specifically designed for demanding environments as a management tool allows plants to view and quantify the product in process streams and wastewater. This allows for more informed process control and incident response ultimately leading to reclaimed profit that would have otherwise been lost.

Parameters Relevant in Product Loss Applications:

Wastewater

Wastewater management is a journey that evolves from laboratory measurements to automatic online process control and finally to smart optimization systems.

As one of the most resource intensive processes in your plant, the demands to minimize environmental impact and ensure compliance of discharge requirements are many.

From nutrient removal to sludge treatment to sampling, proper monitoring and treatment reduces costs in both reagents and the prevention of permit violations.

Parameters Relevant in Wastewater Applications: