Optimize production performance swiftly and confidently

Using the right analytics solution can help electroplating and coating manufacturers ensure product quality, optimize production processes to support water conservation, and ensure regulatory compliance.

Every day you make choices regarding product releases, process adjustments or responses to new issues. When making important decisions like these, you need to be confident in the data available.

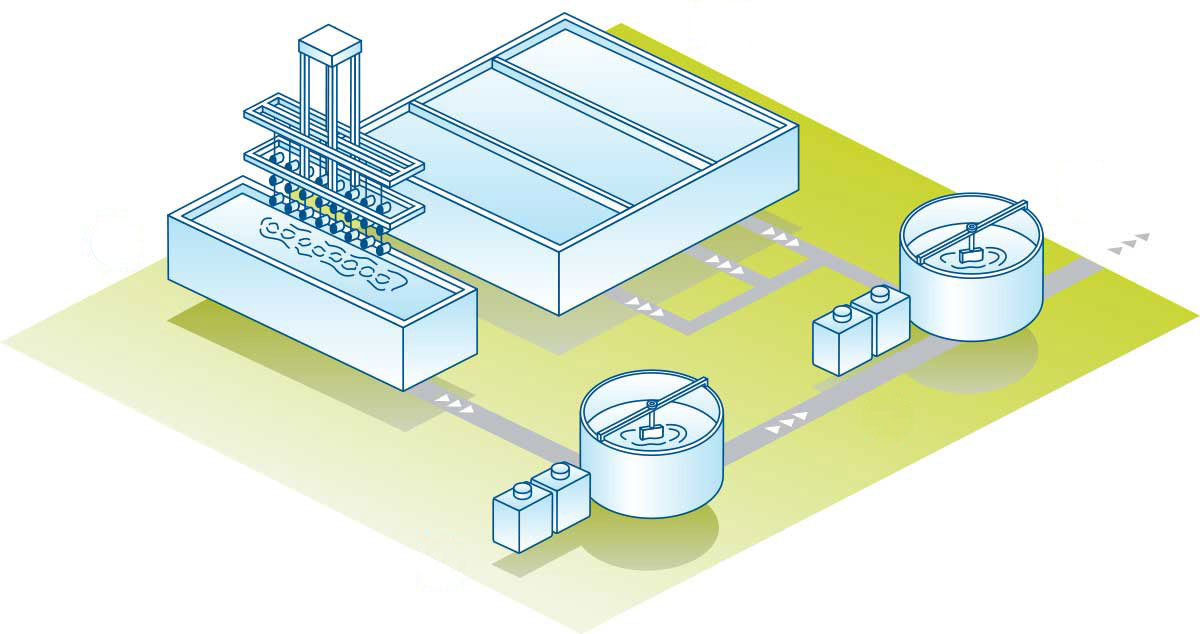

Hach is committed to supporting producers in the plating and coating industry as they navigate the roll-out of new total suspended solids (TSS) standards that drastically drop permitted levels. Are your clarifiers and other traditional equipment performing optimally? Accurate TSS measurements can provide peace of mind—or a plan of action to correct discharge levels.

Global cyanide discharge requirements are also tightening, which may affect your choices in membrane technologies and biological treatment for rinse baths, detoxification and discharge applications. Will your current cyanide levels measure up? Know for sure with test kits and online analyzers.

Choosing a Hach analytics solution enables plating plant operators to:

- Maximize uptime. Robust, accurate analytics solutions help manage processes and optimize production.

- Maintain quality. Specifically designed analytics can ensure high quality standards.

- Maintain compliance. Years of development ensure you can do this safely, easily and economically.

- Protect your investment. The right analytics are key to long plant life, cost savings and compliance.

- Benefit from partnering. Local technical support and service deliver adapted analytics solutions.

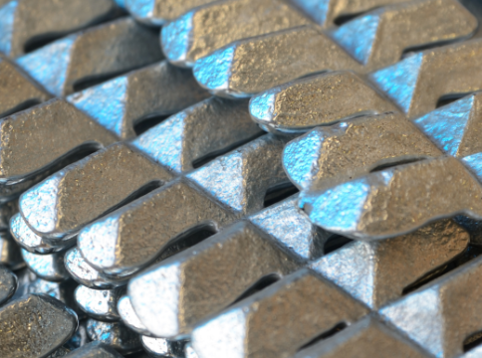

Immersion Baths

Monitor treatment process in immersion baths to ensure quality control of products that comply to specifications, optimize production performance and extend bath service life.

Parameters Relevant to

Immersion Baths:

Chrome bath color

Chrome bath color

Copper bath color

Copper bath color

Chrome bath color

Chrome bath color

pH value

pH value

How to Measure:

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.